Mining

OTR’s product lineup for vehicles used in surface and underground mining is the result of many years of experience, innovations, and a hands-on approach that ensures our products get the job done. Whether you are focused on vehicle productivity, utilization, safety, or value, OTR’s team will help you find the right solution.

OUR PRODUCTS:

Standard OTR Wheels

- Designs and sizes compliant with industry standards; compatible as replacements for all wheel brands used in market.

- Full penetration welds with 100% phased array ultrasonic (PA) inspection to assure weld integrity and long-life.

- OTR wheels produced in ISO 9001 registered facilities.

Heavy-Duty Wheels

- Fully-machined lock ring grooves for precise fitment and stress relief.

- Fully-machined O-ring grooves for optimal sealing and air pressure retention.

- Heavy-duty back sections for extreme loads and duty cycle.

- Notched rim bases; outdoor driver pocket options available.

- Special alloy steel option for wheels used in high-pressure applications. Consult with your OTR salesperson for more information.

- Valve hole size/placement options for select rim bases.

Large Diameter Wheels (49″–63″)

- HSLA-grade steel used for critical components.

- Seamless forged gutters and fully-machined sections.

- Integrated bead seat Sur-Loc design to prevent inflation when using incorrect mounting ring.

6- & 7-Piece Quick-Change Wheels

- Designs enable demount and vertical mounting without having to remove inside dual tire.

- Compatible with popular fitments and replacements of other brands used in market.

Underground Mining Wheels

- Seamless forged sections for all critical components.

- Fully machined flanges, gutter, and back sections ensure mating component parts have exact fitment needed with evenly distributed stress for reduced wear.

Wheel Inspection & Recertification

OTR’s after-sale support includes a proven wheel inspection and recertification process for vehicles used at mine sites. This capability is enhanced by OTR’s experience in developing and supplying heavy-duty wheels to OEMs, resulting in a core competency that can be leveraged for dealers and end users alike. If wheels are determined to be defective, OTR will work with the OEM, dealer, or end user to specify and supply OEM-approved replacements. The process employed ensures safe demounting with documentation for future reference.

Proper wheel inspection and maintenance is an essential part of keeping your equipment running safely while minimizing downtime.

WHAT WE OFFER:

Wheel Inspection Training: On-site training and certification.

Wheel Inspection Kits: Unique Go/No-Go gauges developed by OTR Canada to measure wear on critical wheel and rim areas.

Wheel Tracking: Through our database, we will track the maintenance and history of your wheels.

Reports: We provide detailed inspection reports on all wheel inspections and repairs.

Wheel Repairs: Complete wheel inspection, recertification and replacement of wheel centers, gutters and back sections.

Replacement Parts: We maintain a large inventory of replacement wheels, lock rings, flanges and bead seats to serve your requirements.

Support: We offer engineering, technical support and over 30 years of experience in the wheel business.

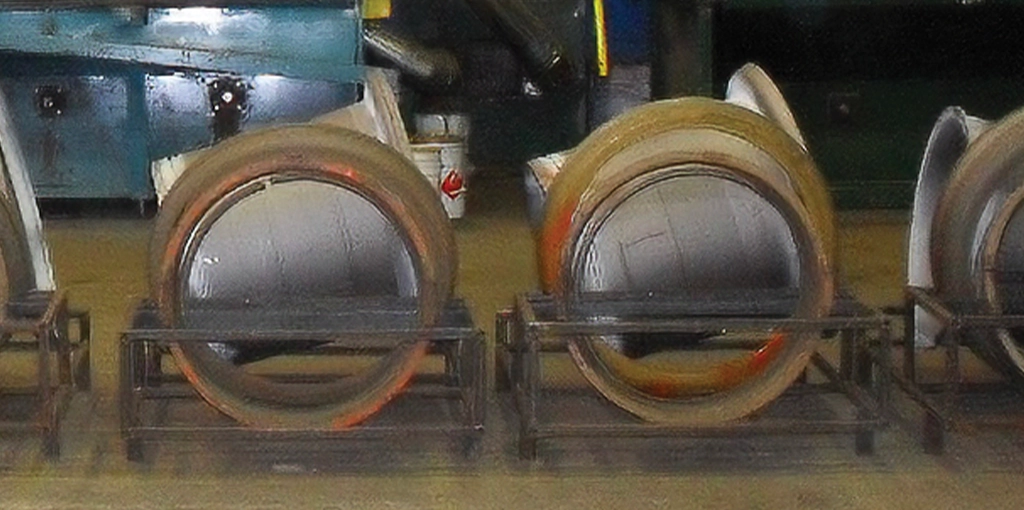

Our process for recertifying mining vehicles:

Step 1:

Incoming Wheel for Recertification

Step 2:

Shot Blasting

Step 3:

Gauge Testing

Step 4:

MPI Testing

Step 5:

Paint Line

Step 6:

Certified Wheel Ready for Delivery

PARTICIPATING LOCATIONS:

Rome, GA USA

6 Riverside Industrial Park NE

Rome, GA 30161

P: 800.833.6309

ISO: 9001-2015

Jacksonville, FL USA

1044 Lane Ave. N

Jacksonville, FL 32254

P: 904.786.7542

ISO: 9001-2015

Sault Ste. Marie, ON

1667 Trunk Rd.

Sault Ste. Marie, ON P6A 6X9

P: 705.942.8484

ISO: 9001-2015

Sudbury, ON

1818 Old Falconbridge Rd.

Sudbury, ON P3A 4R7

P: 705.524.2053

ISO: 9001-2015

Saskatoon, SK

822 56th St. E

Saskatoon, SK S7K 5Y8

P: 306.665.5515

Edmonton, AB

14803 114th Ave. NW

Edmonton, AB T5M 2Y8

P: 780.455.5177

ISO: 9001-2015